Engineering & Development

We provide end-to-end solutions for design development, rapid prototyping, injection molding, DFM, DFMA, mold design, and mold flow analysis—equipping you with the expertise and technology needed to turn ideas into reality.

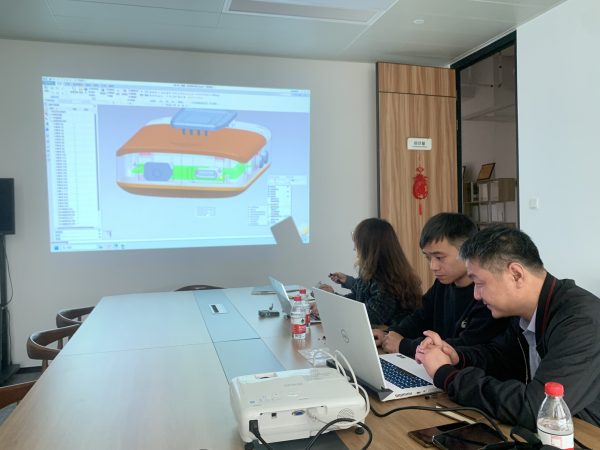

Bringing a product from design to production involves numerous challenges, and having a reliable partner is crucial. Our R&D team stays at the forefront of industry advancements, continuously optimizing designs, enhancing manufacturing processes, and developing innovative solutions tailored to your requirements.

Collaboration drives success. We assign dedicated project teams to manage each stage, with experienced project managers acting as your direct representatives and independent overseers, ensuring every detail is executed with precision and efficiency.

Engineering Capabilities

Our engineering expertise covers every aspect to avoid risks before you invest the big molds;

Design Development & Optimization

Feasible, cost-effective 2D/3D designs developed & refined for quality, efficiency, and risk reduction.

Prototyping

CNC machining, vacuum casting, sheet metal validate designs and minimize early-stage risks.

DFM & Mold Flow Analysis

Preventing defects like shrinkage, sink marks, and demolding issues through advanced simulations.

Design Failure Mode Analysis (DFMA)

Identifying design flaws early to reduce failure risks and costly recalls.

Mold Design

Precision-engineered solutions with features like interchangeable cores, hot runner systems, and multi-cavity molds.

Structural Performance Testing

Evaluating strength, durability, and environmental resistance to ensure reliability and safety.

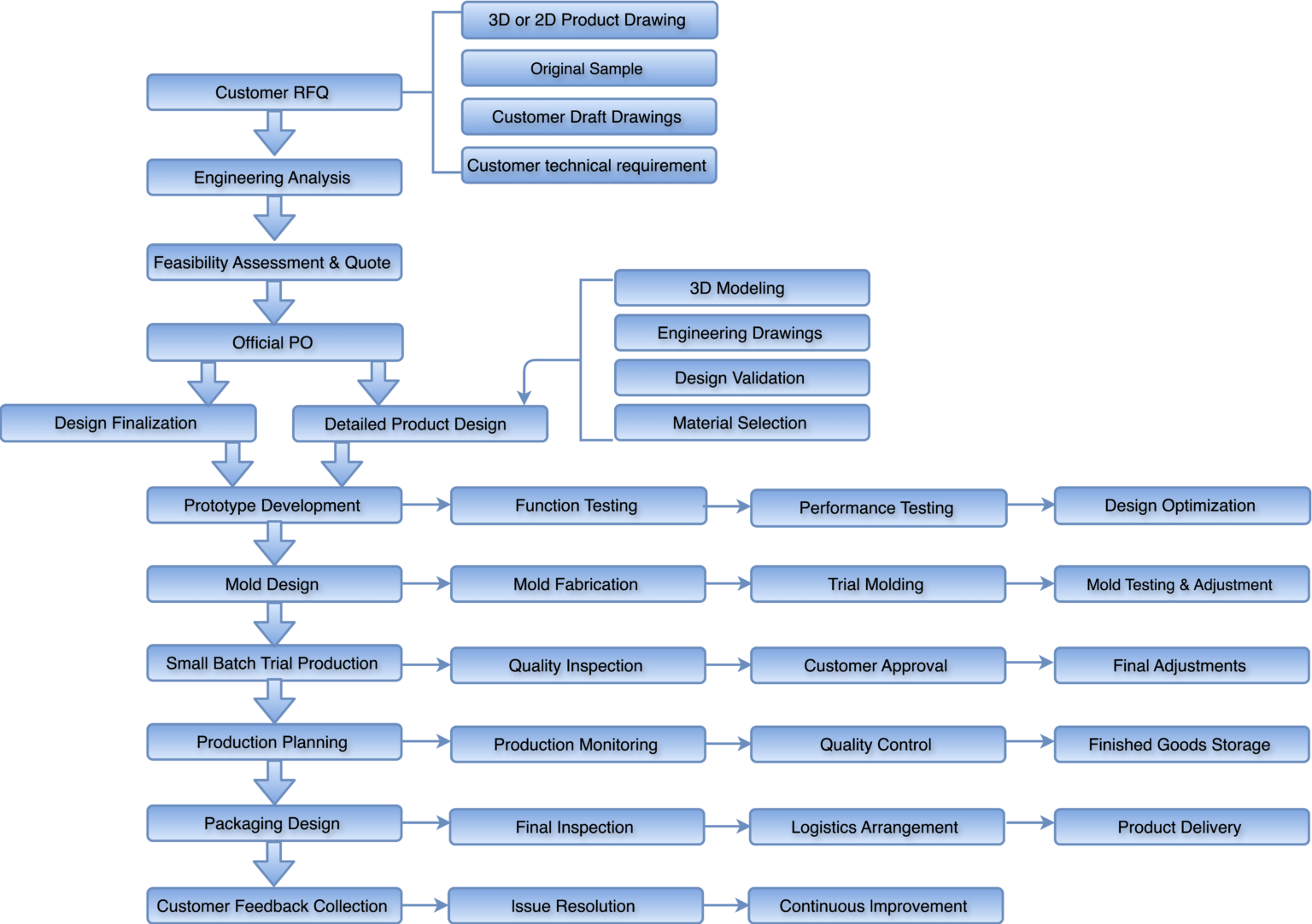

Comprehensive Product Development, Manufacturing, Delivery, and After-Sales Process